PLANT FOR CONVERTING PLASTICS INTO WAX DEPOL40, PARAFFIN AND FUELS

1.1. The purpose of the installation

The plant is designed to convert plastics into liquid fuels or polymer wax.

1.2. The installation is classified under PKWiU number 29.56.25-90.00

Containerized plant for converting plastics into polymer wax and a cooperative containerized plant consisting of a wax gasifier and a combined heat and power unit were designed to of converting plastics into a product that can be easily stored and transportable, and converted into fuels or electricity.

Thus constructed, the device is dedicated to be installed wherever there is a lack of readily available electricity.

1.3. Technical data

The volume of input processed by the plant from 5500 to 6000 kg/h*

- The volume of production of fuels or wax after filtration, assuming a water content in the input of 0.5% (losses on filtration - from 5% to 10%):

- ON/Wax - 2200 l/h

- Gasoline - 375 l/h

- hydrogen - 120-140 kg/day

Supply voltage: 240/400 V

Frequency: 50 Hz

Installed power: 98 kW (depending on additional equipment) Monthly electricity consumption: 68,000 kWh

Recommended height of the production hall: min. 8,5 m Recommended production hall area for PCP700: min. 24 x 35 m Recommended batch storage area: min. 24 x 20 m

Capacity of process water cooling system: 2,5 m3

The average consumption of water used in the process is about 4,000 liters per month and is related to climatic conditions.

*The capacity factor given is related to the type of plastics being processed and the degree of their contamination.

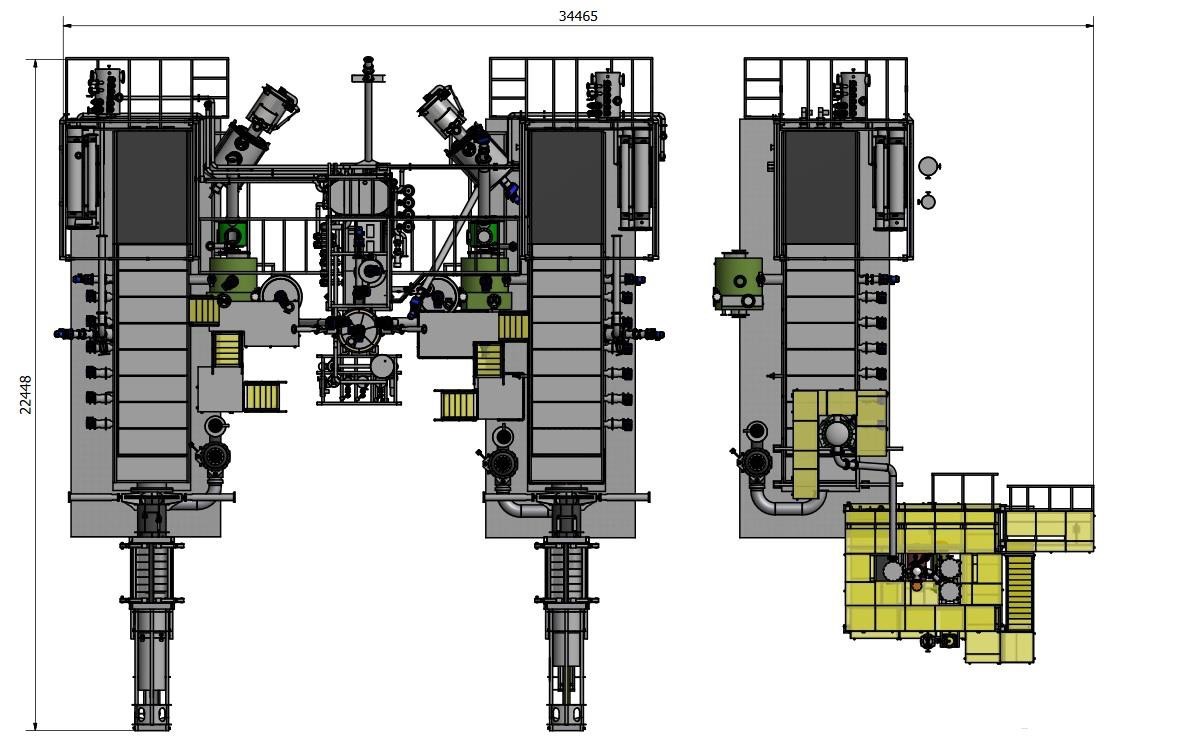

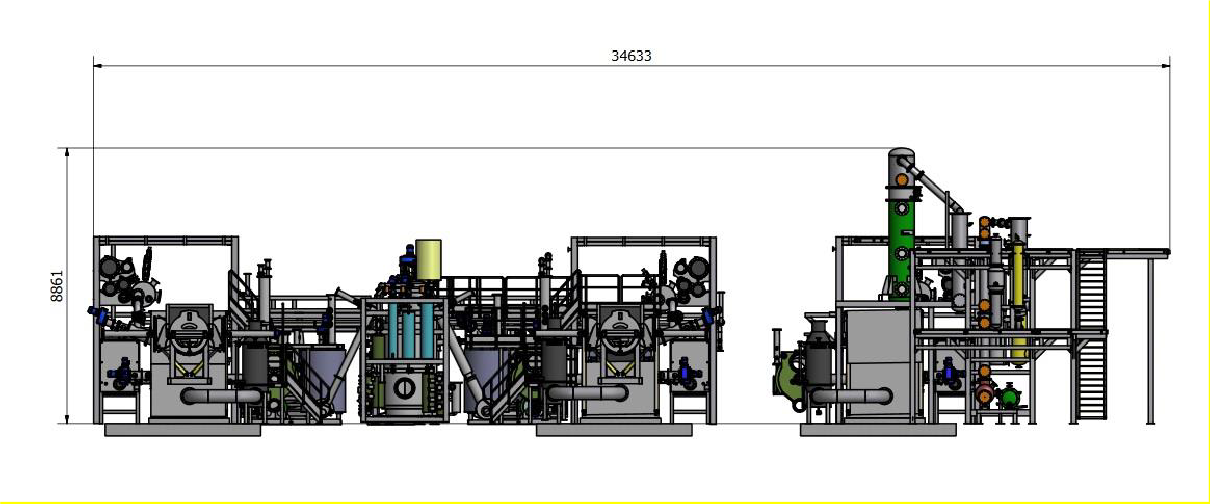

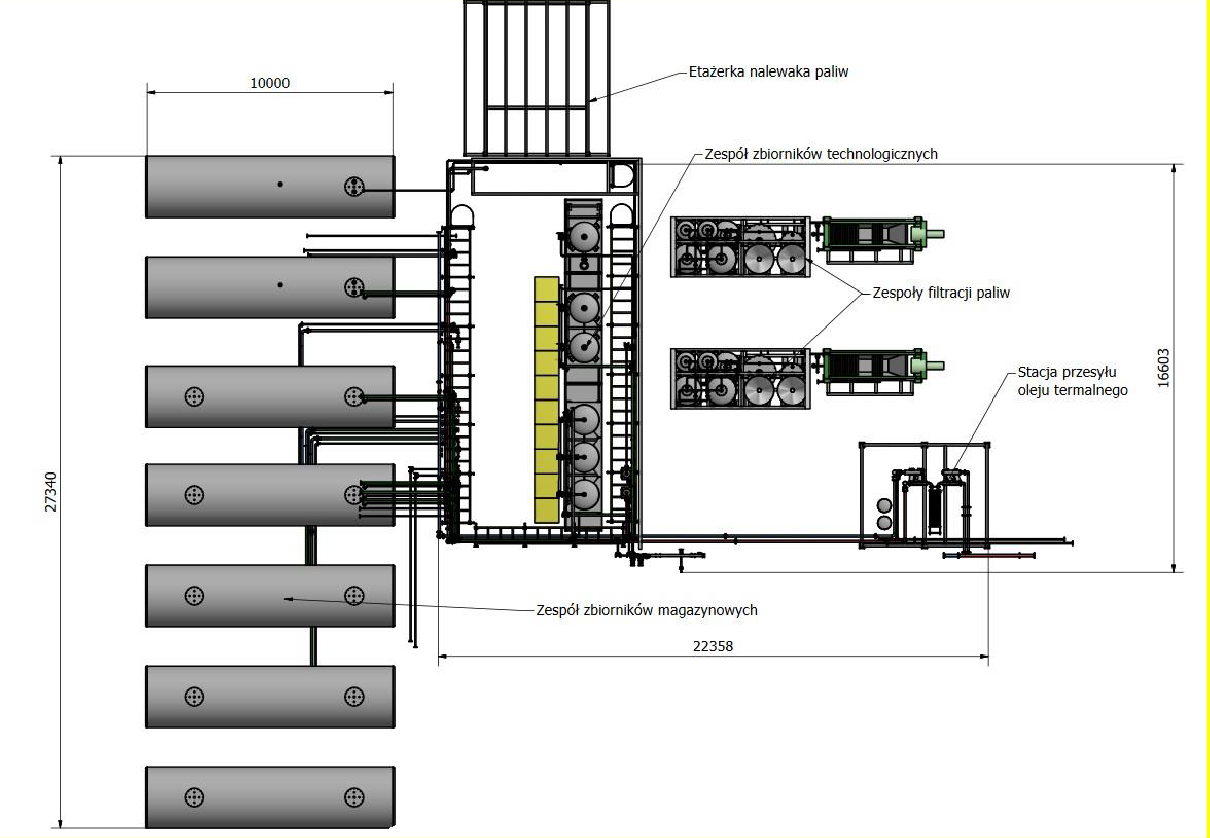

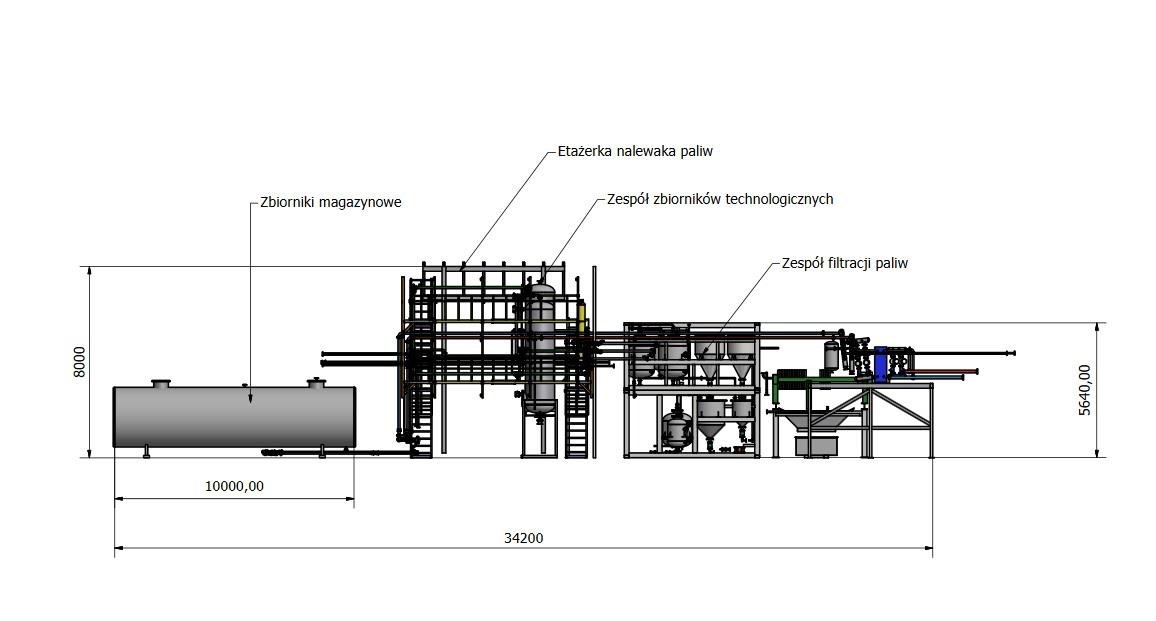

The drawings below show the installation in plan view.

Figure 01: Top view of the installation.

Figure 02: Side view of the installation

Figure 03: Top view of the storage tank station, filter assembly and process tanks.

Figure 04: Side view of the tank station, filters and process tanks. The primary processing unit for plastic waste is the catalytic reactor.

1.4. Description of the operation of the installation

The basic processing unit for plastic granulates or re-granulates is a catalytic reactor. At the entrance of the reactor there is an automatic feeding and dosing system for hydraulically driven plastics. The feedstock to the batching system is fed mechanically using screw feeders. The feedstock is fed into the reactor after the atmospheric air is pumped out of the feedstock. Inside the reactor, the feedstock is heated and then melted and subjected to the cracking process. The melted plastics are further heated until degradation occurs at temperatures as low as about 200°C. The end of the process occurs at about 410°C.

The flue gas, after giving up heat in the exchangers, escapes to the outside through a flue pipe. The polymer wax formed in the process is led out of the reactor by a screw conveyor to the wax filter. The reactor is connected to the filter by a hydraulically driven gate valve. The gate valve allows all filter maintenance to be performed without shutting down the reactor. The filter is equipped with a screw conveyor system for continuous or periodic wax removal

Two tubular heat exchangers are built into the system of each reactor. The first of them heats the thermal oil the second one takes the heat from the flue gas lowering its temperature to a maximum of 140 degrees Celsius. In the cracking process, in addition to the wax fraction, a certain amount of light fractions is generated, which after leaving the reactor go to the cooler package, after leaving which they are fed through a dust removal and cleaning filter, a dehumidifier and a distributor into the burners of the reactor or the burners of the water evaporation column. The liquid wax is led out by a screw conveyor to the wax filter. The liquid wax is received from the wax filter by a linear wax pump driven by an electric motor. The wax is pumped to the granulator buffer tank via a pipeline with a temperature stabilized pipeline jacket.

The wax granulation unit is built with a pipeline that transports liquid wax from the wax filter to the granulator buffer tank.

Liquid wax is drawn from the granulator's buffer tank and transported to the plant's module B. The liquid wax taken from the granulator buffer tank of module A is free of water and most impurities, and is therefore an excellent polymer feedstock for the catalytic cracking process taking place in module B of the plant. The granulator buffer tank of module A has the capacity to receive the wax from the two processing reactors. The buffer tank has a heating jaket with thermal oil flowing through it, ensuring that the required temperature levels of the wax inside the tank are maintained. From the tank, the wax, via a cooler, is fed to the pelletizing head or pumped to Module B for further processing. The wax droplets flowing out of the head move by gravity

In the water bath of the wax cooling ramp. The cooled and hardened wax granules are fed into big-bags or storage silos via a screw conveyor.

The polymer wax produced at the plant is used as an additive to modify bituminous masses, can be used in energy processes or converted into activated carbon or liquid fuels. One of the products produced at the plant can be paraffin wax for the manufacture of candles and candles.

The operation of module B of the plant is carried out in parallel with module A. Liquid wax at a temperature of about 360°C is taken from the buffer tank of the wax granulation system of module A and fed through pipelines with temperature stabilized by thermal oil to the catalytic reactor of module B. The hot wax taken from the buffer tank is free of water and most solid impurities. It makes a good material for catalytic cracking occurring in module B.

The wax cracking reactor has a design similar to wax production reactors. Module B is equipped with a tower-tube plant for distillation of hydrocarbon fractions. The final product of Module B's operation is hydrocarbon fractions with an adjustable and adjustable boiling point. For example, it can be a diesel fraction and a gasoline fraction.

The hydrocarbon fractions produced are subjected to further processes including purification of from impurities and are supplemented with additives to provide them with parameters that comply with liquid fuel standards.

The installation has a container design and can be built from four to twelve 40" containers:

- Container with reactor that converts plastic waste into polymer wax:

- can work independently converting plastics into fuel or an additive to fossil fuels increasing their calorific value and reducing environmentally harmful emissions including carbon dioxide emissions,

- Container for purification and separation of the generator gas generated in the depolymerization of plastic waste and separation of the generator gas generated in the wax gasification plant,

- Wax storage container (fuel buffer),

- A container containing a wax gasifier and a cogeneration generator with an output voltage The wax gasification plant simultaneously provides a source of gas to power the burners operating in the reactor that converts waste into waxes, which reduces the cost of wax production and makes the unit virtually independent of external fuels.

A functional diagram including the system for wax production, transport and storage is shown in the figure below. The final product obtained by the technological process goes under the trade name DEPOL 40 and is a polymeric wax with high energy properties.

Figure 05: An illustrative functional diagram of the system.

The energy contained in the wax can be stored and stored for any length of time without losing any of its qualities, the transportation of wax is completely safe for the environment, wax does not pollute water, soil and air.

The tested product - polymer wax - is a good material for the production of composite fuels, improving the properties of the base fuel. The compatibility of physicochemical characteristics with typical thermal coal allows to use the mechanical properties of the wax without leaving a clear trace in the combustion products of the composite fuel.

A sample of wax obtained from the processing of polyolefin plastics with potential for use in energy processes was tested. All tests carried out were performed at the Central Measurement and Research Laboratory Sp., z o.o., an accredited testing laboratory in accordance with PN-ISO 17025:2009 (accreditation certificate AB 300). The scope of AB 300 accreditation includes, among others, testing of solid fuels, biomass and alternative fuels. The data obtained testify of many desirable characteristics:

- low total moisture content (0.6%),

- average ash content (8.6%),

- high calorific value (38-40.8 kJ/g),

- Low emission rate (70.1 MgCO2/TJ),

- low sulfur content (0.15%),

- Ash fusibility similar to that of coal ash,

- low content of basic oxides, e., sodium oxide and potassium oxide.